How to produce laboratory glassware?

Producing laboratory glassware involves a specialized manufacturing process that requires precision and attention to detail to meet the stringent requirements of scientific and research applications. Laboratory glassware is used in a wide range of scientific experiments, chemical analyses, and medical research. Here is an overview of the typical steps involved in producing laboratory glassware:

Glass Selection: The first step is to select the appropriate type of glass for the specific laboratory glassware being produced. Borosilicate glass is a common choice due to its exceptional thermal resistance and chemical inertness, making it suitable for a wide range of laboratory applications.

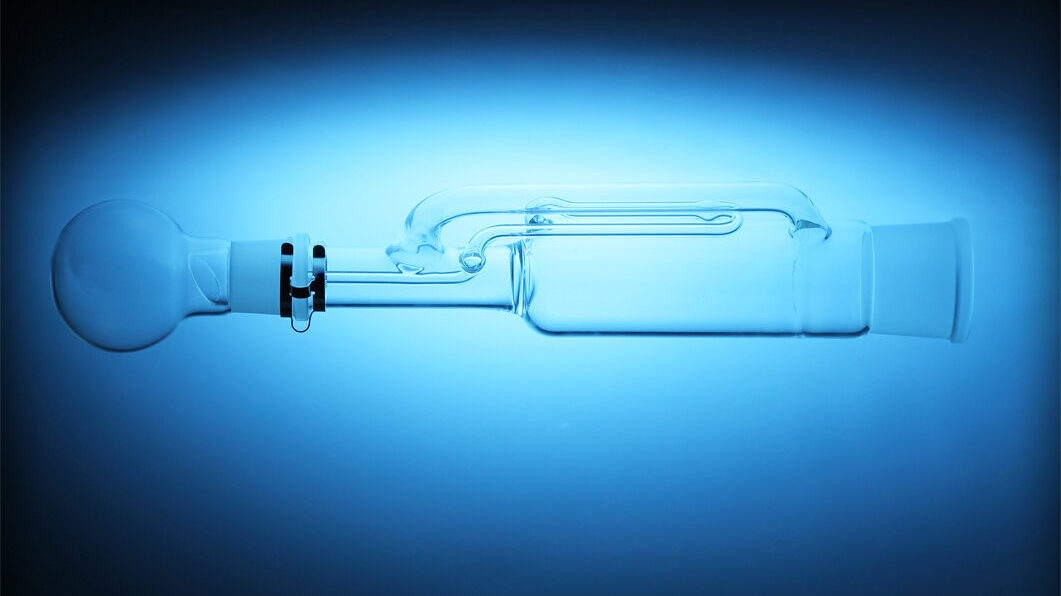

Glassblowing or Glass Forming: The glassblowing process is a traditional method used to shape glassware by heating the glass until it becomes malleable and then forming it using various tools and techniques. Skilled glassblowers can create complex shapes such as beakers, flasks, test tubes, and pipettes. For more intricate and precise shapes, automated or semi-automated glass forming methods may be used.

Annealing: After the initial shaping, the glassware is subjected to an annealing process to relieve any internal stresses created during forming. The glassware is heated to a specific temperature and then slowly cooled in a controlled manner. This process ensures the glassware's structural integrity and reduces the risk of breakage during use.

Cutting and Sealing: Some laboratory glassware, such as graduated cylinders or volumetric flasks, requires precise measurement markings. These markings are often made using diamond or laser cutting techniques. Additionally, glass tubing may be sealed using a flame to create various glassware components like pipettes and burettes.

Surface Treatments: Some laboratory glassware requires special surface treatments. For example, filtration funnels may undergo surface hydrophobic treatment to facilitate efficient filtration.

Quality Control: Quality control is an essential step in the production process to ensure that the laboratory glassware meets the required specifications. Each piece is thoroughly inspected for any defects, dimensional accuracy, and performance before being released for sale or use.

Packaging: Once the glassware passes the quality control tests, it is carefully packaged to prevent breakage during transportation and storage. Proper packaging is crucial to ensure that the glassware arrives at its destination in perfect condition.

It is important to note that producing laboratory glassware requires skilled craftsmanship and adherence to strict quality standards. As such, many manufacturers specializing in laboratory glassware have highly trained glassblowers and quality control teams to ensure the final product's accuracy, reliability, and safety.

Moreover, the production of laboratory glassware may also involve specific requirements based on the intended use and the industry standards, such as ASTM or ISO specifications. Following these standards ensures that the glassware meets the needs of the scientific community and maintains the highest level of accuracy and reproducibility in laboratory experiments and analyses.